1.F Model dissociated and MBR Model monoblock burners can be retrofitted. Specific models are as follow:

FOL2800、FOL2500、FOL1600、FOL1500、FOL1000、FOL750、

FL2800、FL2500、FL1600、FL1500、FL1000、FL750、

MBROL2800、MBROL2500、MBROL1600、MBROL1500、MBROL1000、MBROL750、

MBRL2800、MBRL2500、MBRL1600、MBRL1500、MBRL1000、MBRL750、

2.Configuration

No. | Item | Qty. | Note |

1 | Natural gas gun | TBC | The number of guns depends on different models |

2 | Natural gas deflector | 1 | |

3 | Natural gas ring | 1 | Need to check if has been pre-configured |

4 | Natural gas flow control valve | 1 | |

5 | Natural gas valve group | 1 | |

6 | Natural gas pipelines | 1 | Need to be prepared by customer at job site |

7 | Control system retrofitting | 1 | Siemens leak detection controller, relay knob etc. |

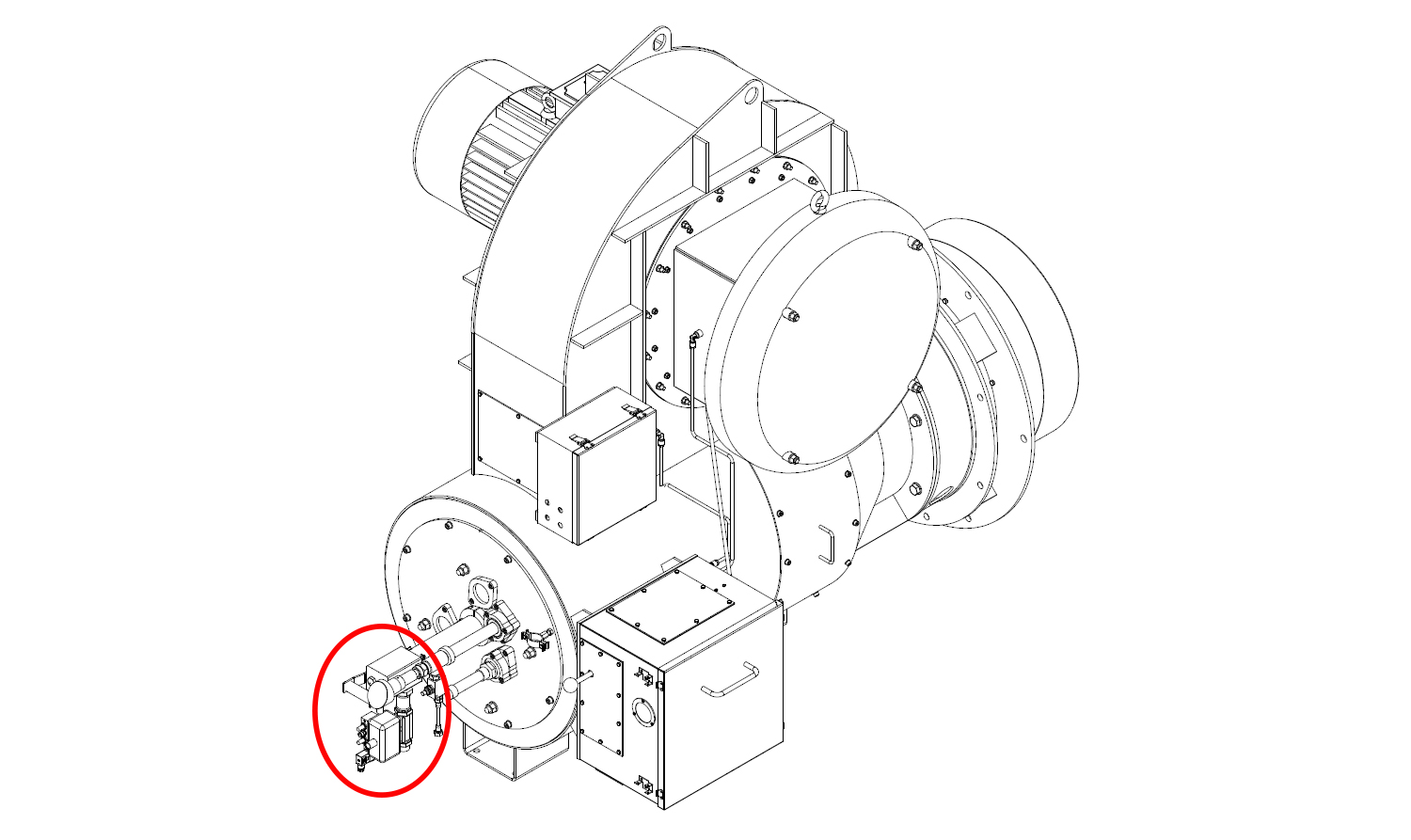

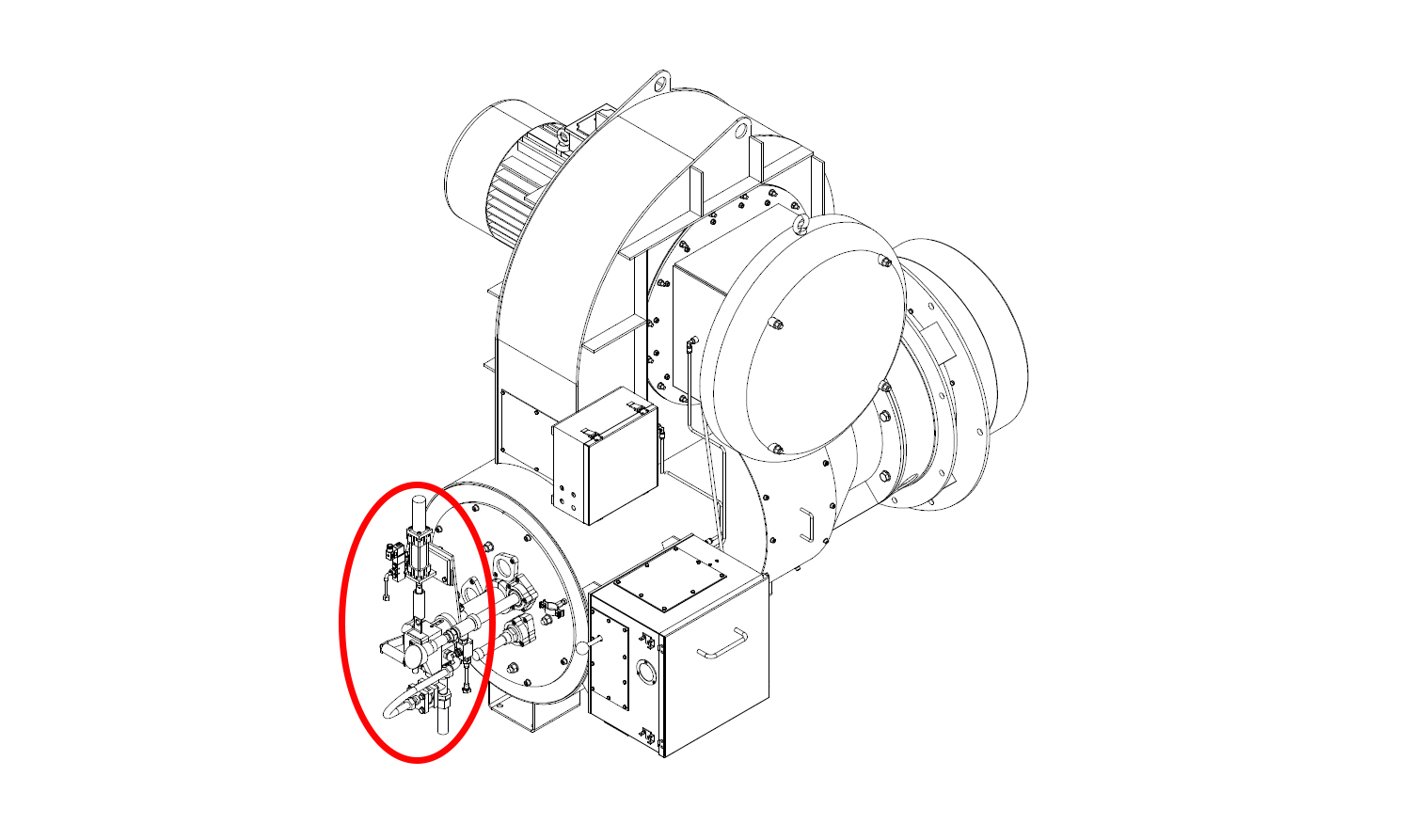

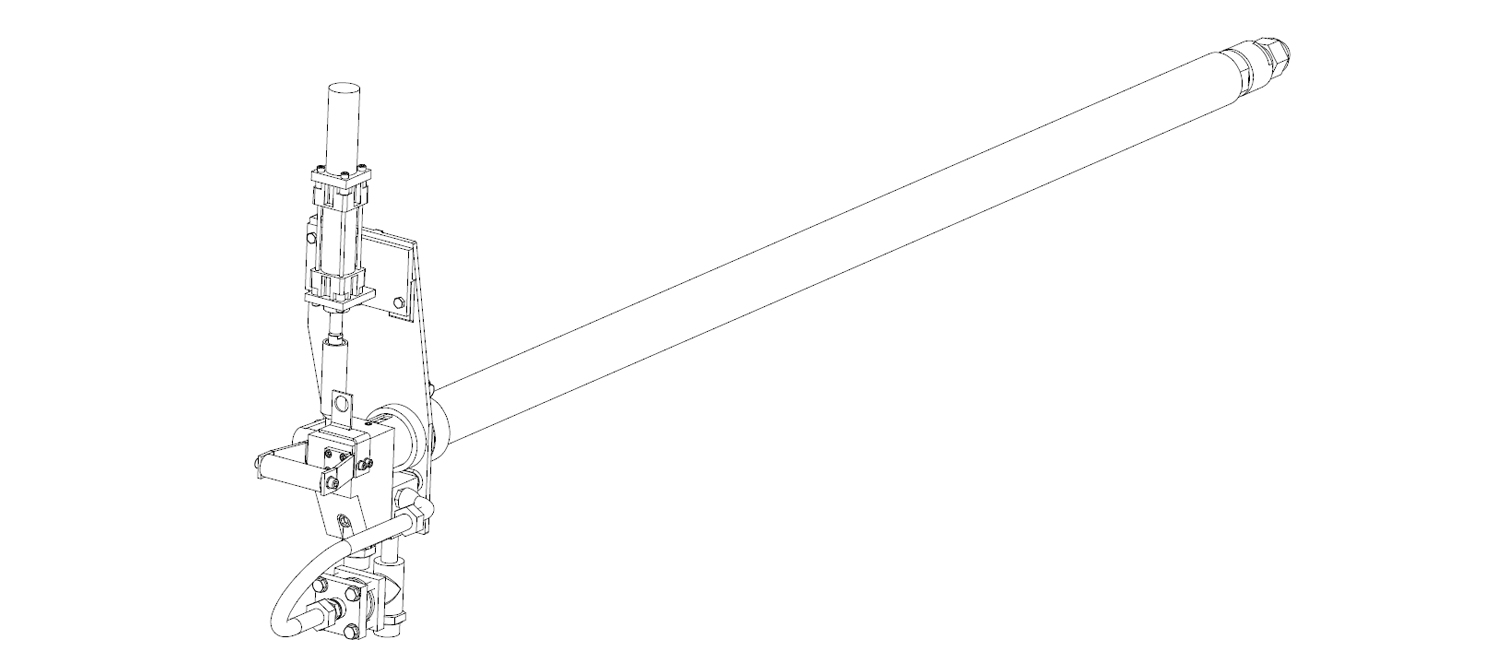

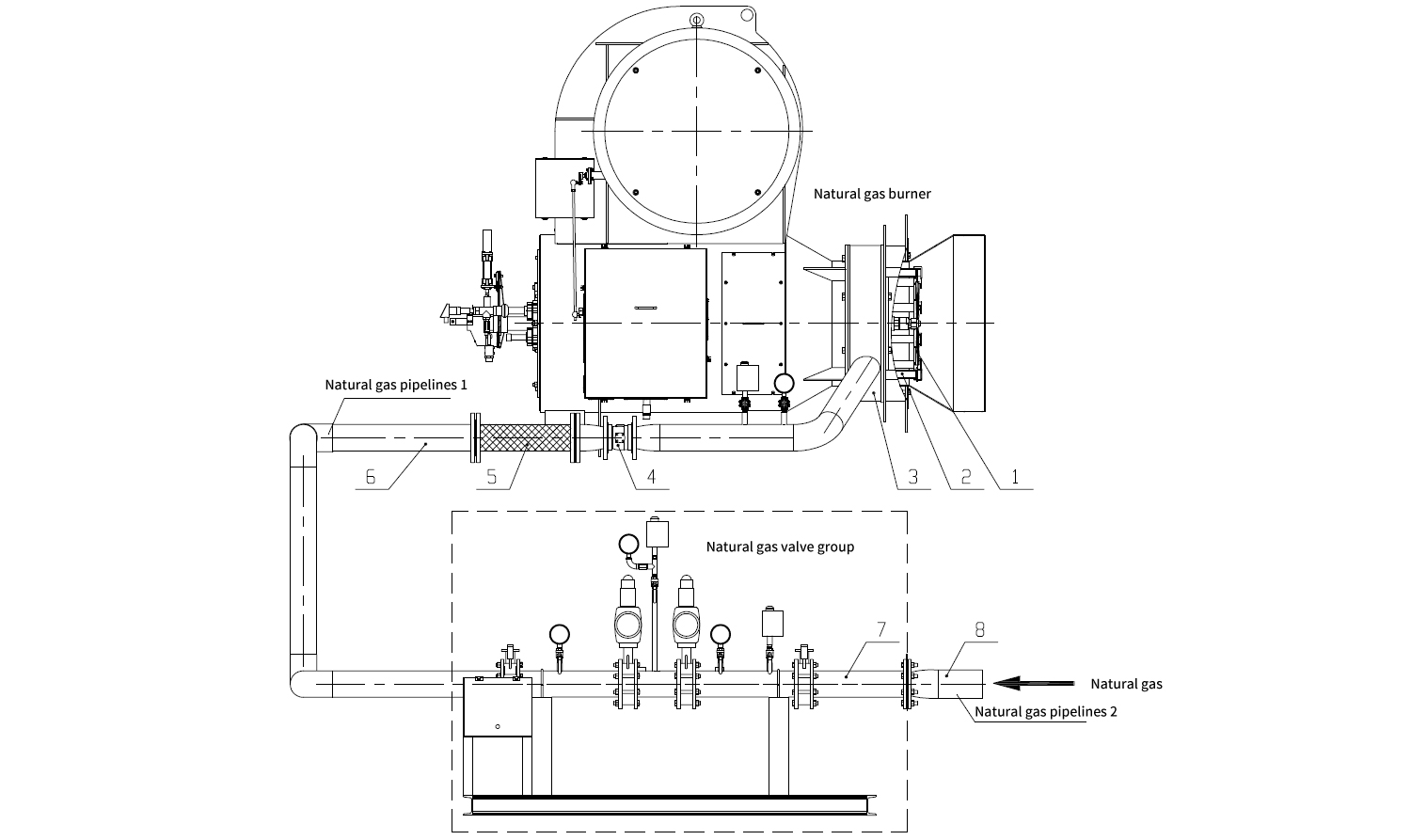

3.Schematic Diagram

No | Name |

1 | Natural gas gun |

2 | Natural gas deflector |

3 | Natural gas ring |

4 | Natural gas flow control valve |

5 | Metal corrugated pipe |

6 | Natural gas pipelines 1 |

7 | Metal corrugated pipe (natural gas valve group) |

8 | Natural gas pipelines 2 |

4.Parameters of Natural Gas Burner

Model | Power (Kw/max) | Max. Gas Consumption (Nm³/h) | Calorific Value (KJ/ Nm³) | Pressure(mbar) | Inlet Diameter | Note |

F/MBR-G-2800 | 30000 | 3120 | 34750 | 600 | DN125 | DN150 The diameter of the conveying pipeline should be no less than DN150 |

F/MBR-G-2500 | 26700 | 2780 | 34750 | 600 | DN125 | |

F/MBR-G-1600 | 17900 | 1850 | 34750 | 600 | DN125 | |

F/MBR-G-1500 | 13400 | 1390 | 34750 | 600 | DN125 | DN125 The diameter of the conveying pipeline should be no less than DN125 |

F/MBR-G-1000 | 11200 | 1150 | 34750 | 600 | DN125 | |

F/MBR-G-750 | 8900 | 925 | 34750 | 600 | DN125 |

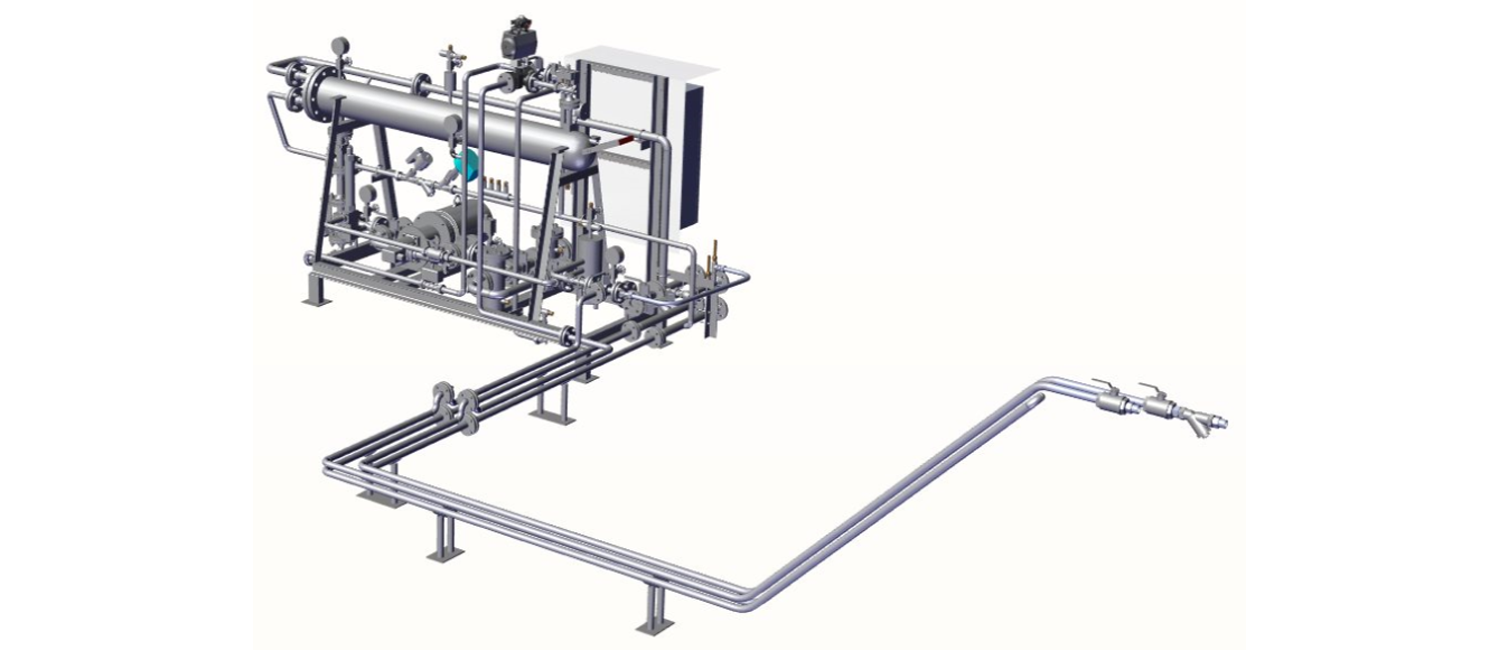

5.Project Case

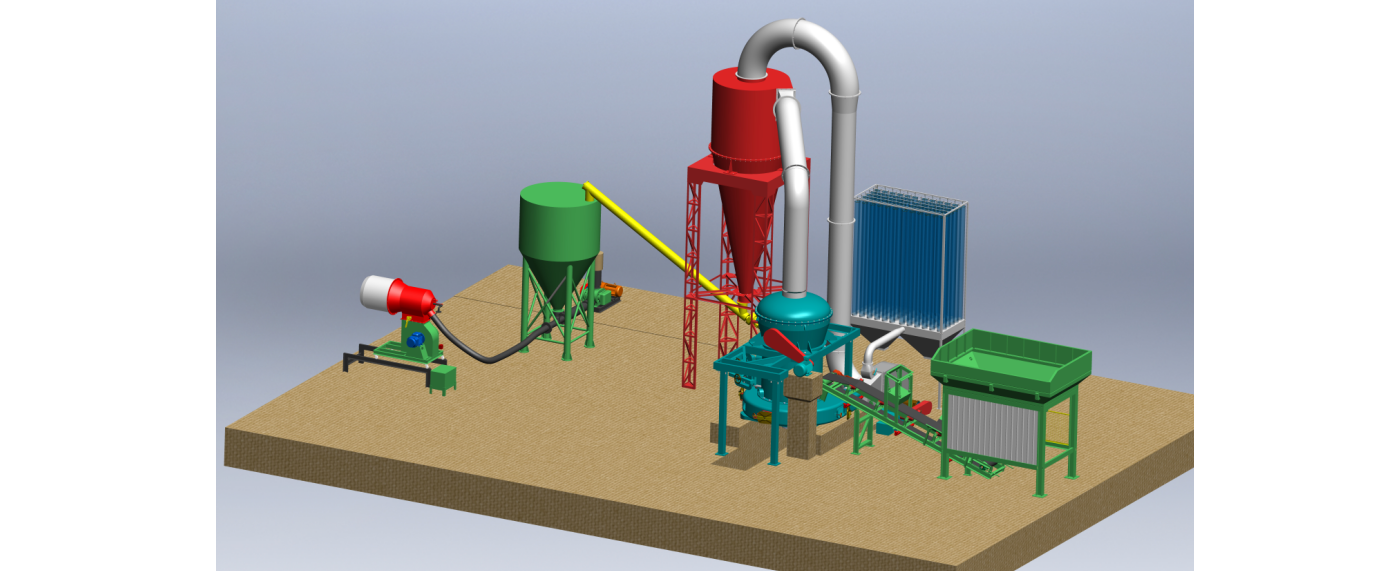

1)Kazakhstan #1009 Burner Retrofit

To retrofit the dissociated heavy oil+diesel oil burner into oil (heavy /diesel oil) gas (natural gas) dual-function dissociated burner, enabling the use of natural gas for combustion

There is gas supply at the customer's construction site. The price of gas is more reasonable than that of diesel and it is more environmentally friendly.

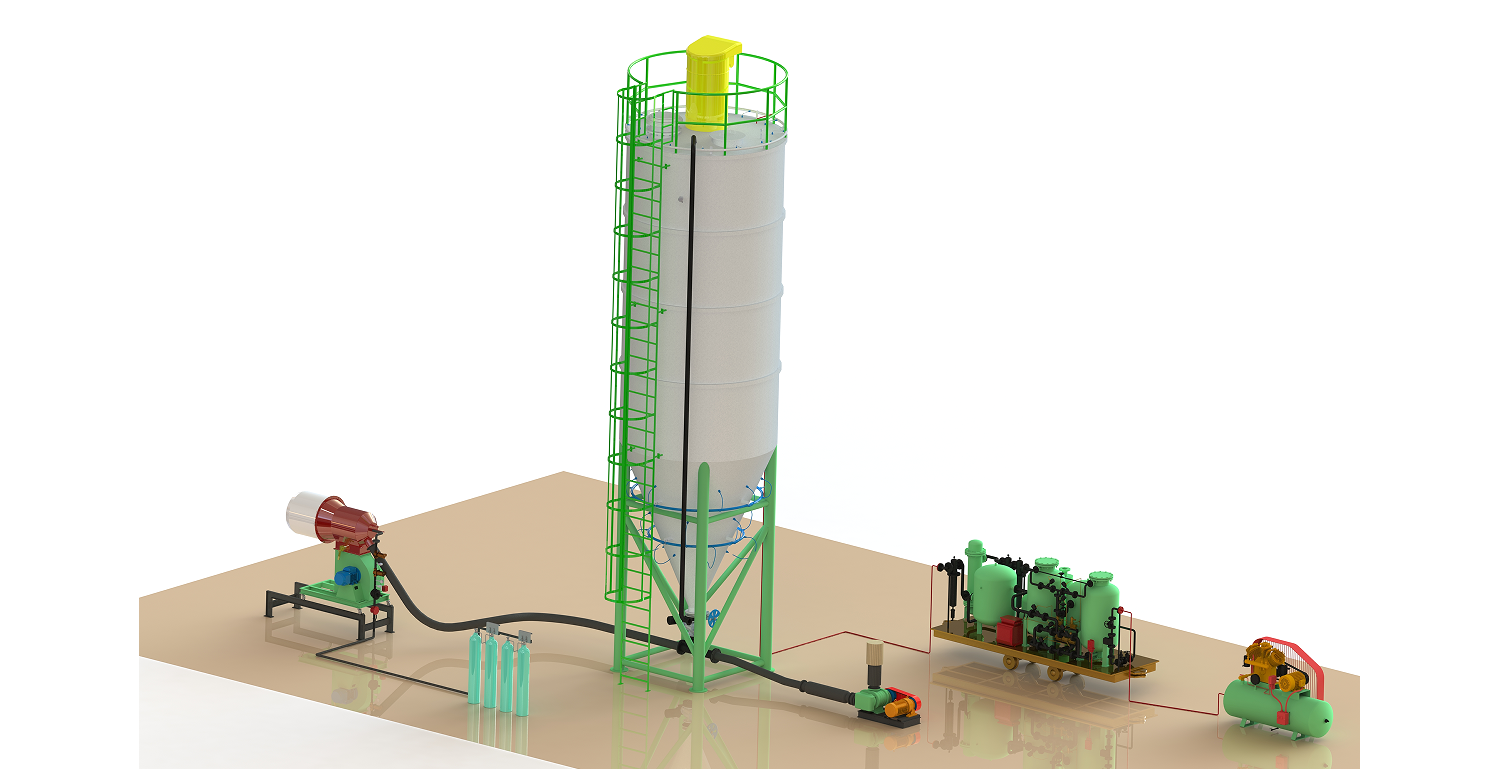

2)Russia Burner Retrofit

The natural gas burner and valve groups of #1226 has been adopted for natural gas burner retrofitting of #815