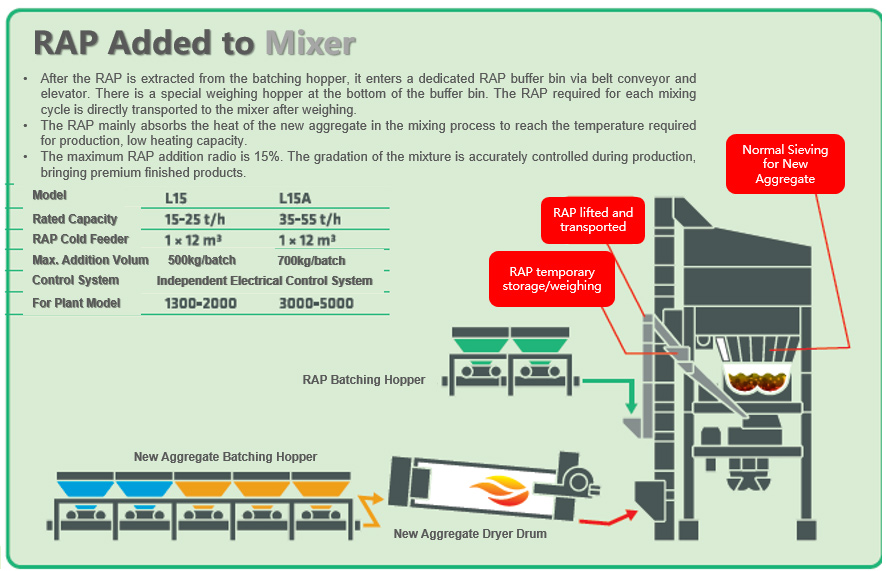

After the RAP is extracted from the batching hopper, it enters a dedicated RAP buffer bin via belt conveyor and elevator. There is a special weighing hopper at the bottom of the buffer bin. The RAP required for each mixing cycle is directly transported to the mixer after weighing.The RAP mainly absorbs the heat of the new aggregate in the mixing process to reach the temperature required for production, low heating capacity.The maximum RAP addition radio is 15%. The gradation of the mixture is accurately controlled during production,bringing premium finished products.

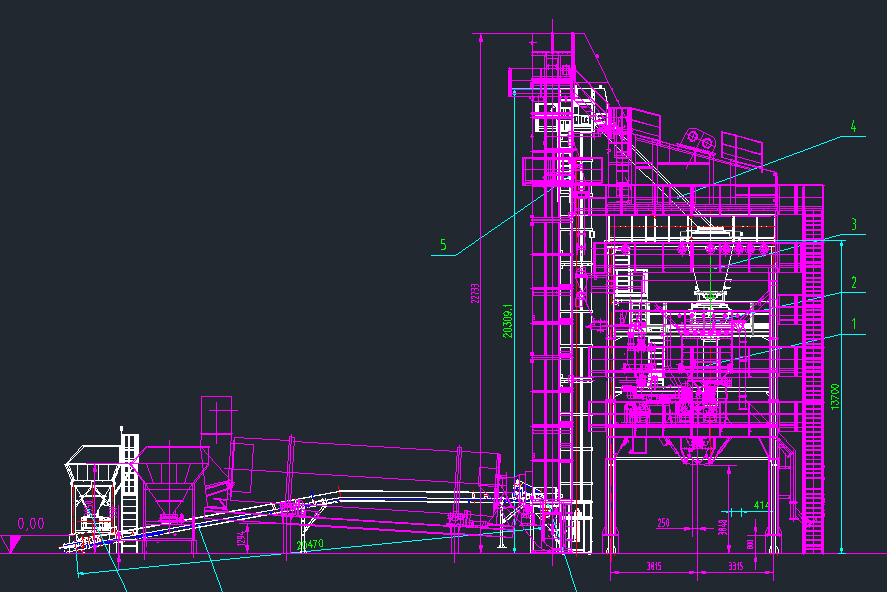

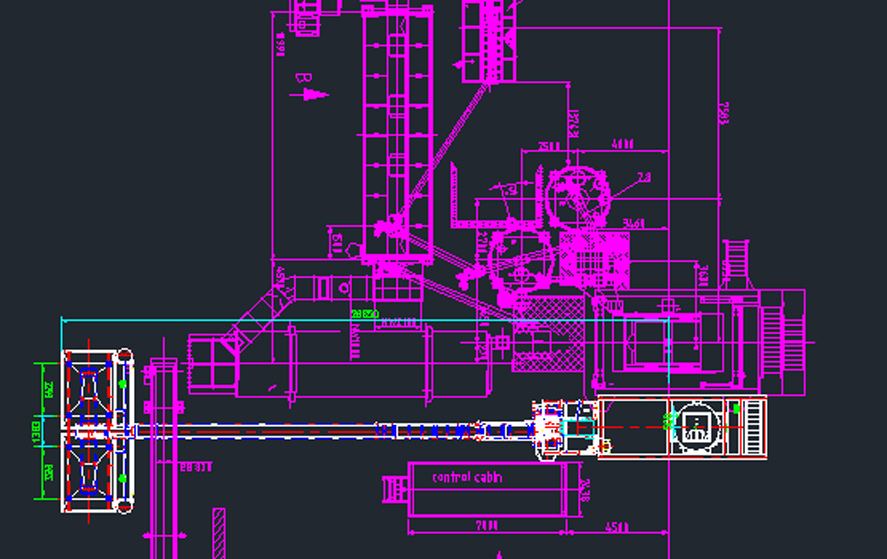

Flow Chart:

Reference of Projects:

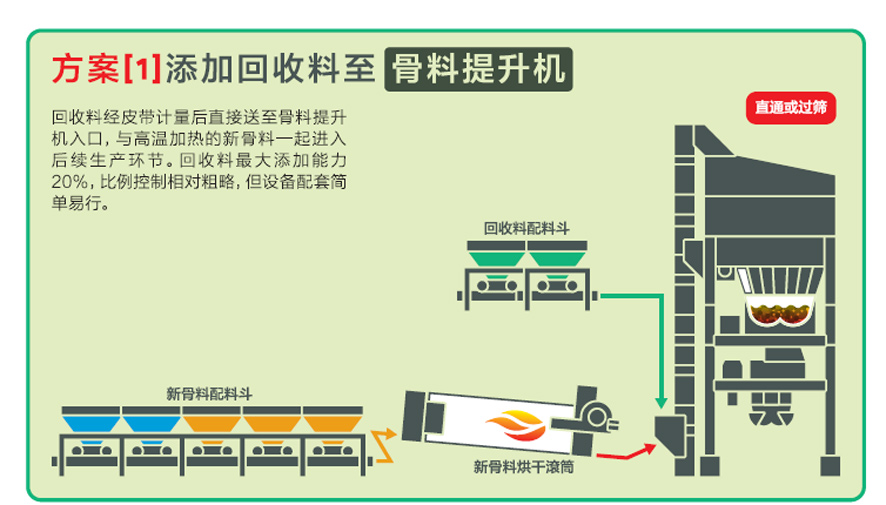

RAP Added to Aggregate Elevator

After the RAP is measured by a belt conveyor, it directly reaches the entrance of the aggregate elevator via the conveyor, where it joins the subsequent production with the new aggregate heated at high temperature. The maximum RAP addition ratio is 20% with rough proportion control, and the simple-structured equipment is easy to operate.

New Aggregate Batching Hopper

RAP Batching Hopper

New Aggregate Dryer Drum

Through or Sieving

Model | L15 | L15A |

Rated Capacity | 15-25 t/h | 35-55 t/h |

RAP Cold Feeder | 1 x12 m³ | 1 x12 m³ |

Max. Addition Volum | 500kg/batch | 700kg/batch |

Control System | Independent Electrical | Control System |

For Plant Model | 1300-2000 | 3000-5000 |