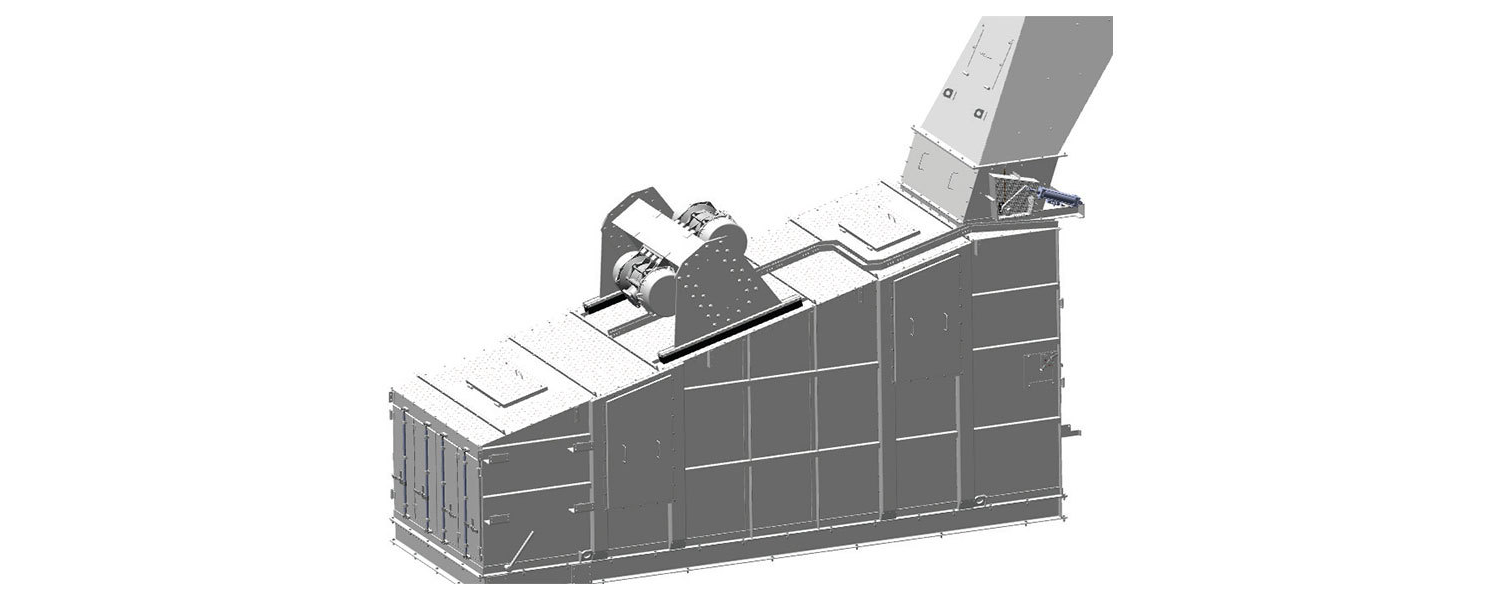

D&G MACHINERY introduced the eco-friendly type aggregate shaping & sand making plant, mainly use such as granite, limestone mine rock and tailings gravel as raw materials, with the vertical shaft impact sand making, vibrating screen, dust collection module, transmission module and other components, make the system complete sets of equipment to green, harmonization, intelligent, service direction, can realize clean production, accelerate transformation of the mode of economic growth has important strategic significance.

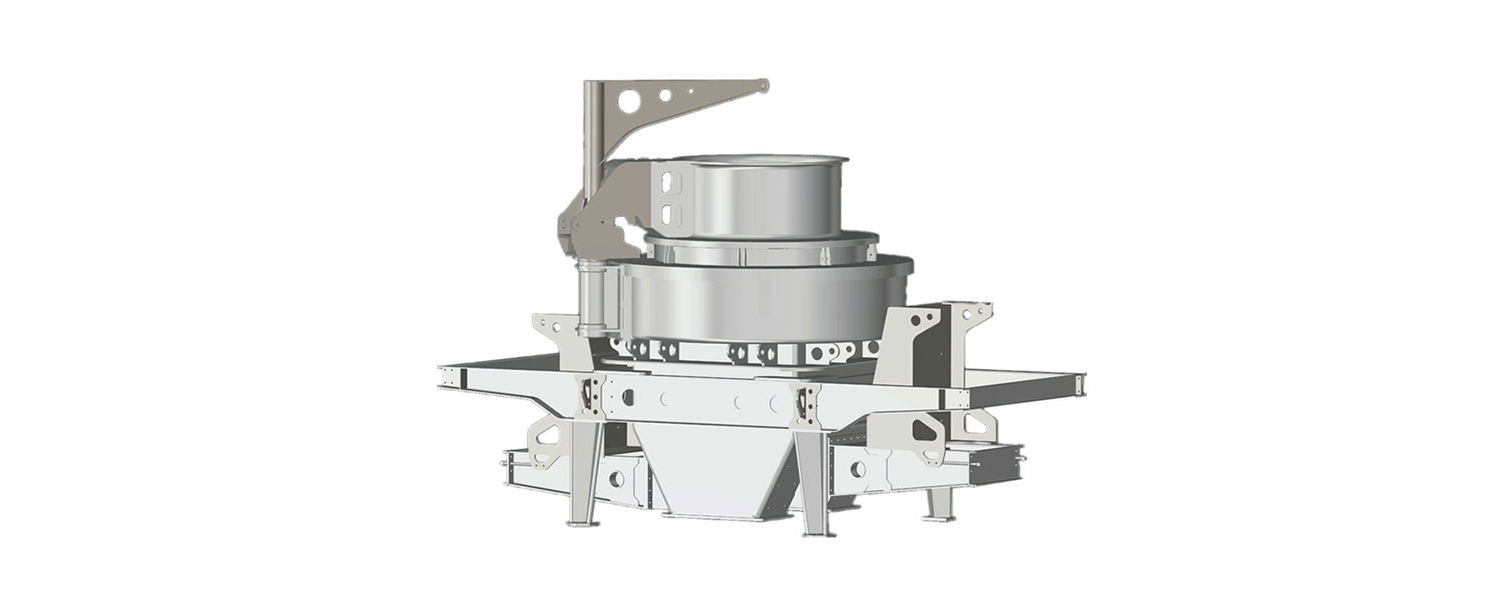

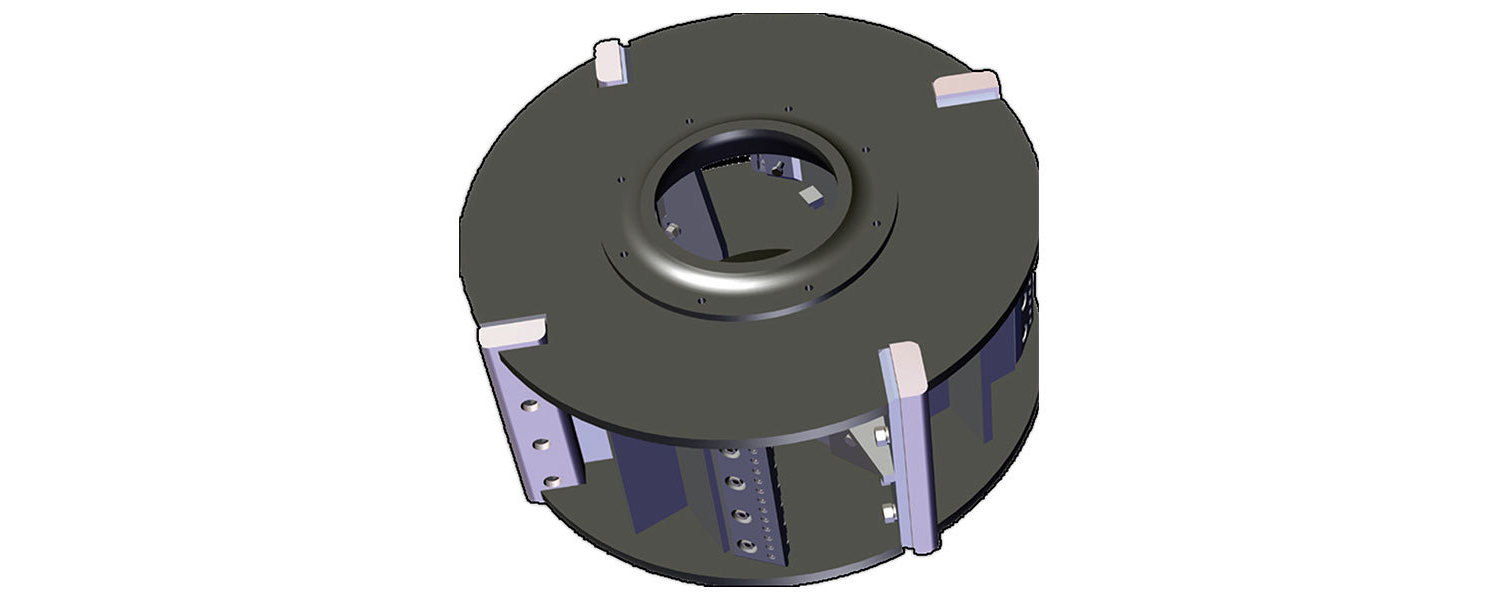

The Four Channels impacted rotor structure integrates crushing, shaping, sand making. With central feeding, the material can obtain the highest kinetic energy (max 80m/s). Without increasing the power, the explosive falls into the material, which can increase the output .

Sand Manufacturing Methods:

Sand-crash-sand:It is applicable to materials with medium hardness or above,with the material good particle shape and slightly more powder content.

Sand-crash-iron:It is applicable to materials with medium hardness or below,with the high crushing efficiency and high cost of wear parts.

(max 10%).

It is high precision sieving stable performance, with multistage screening, large capacity and high screening efficiency and also can be screened according to customer needs, D&G MACHINERY provides scientific production solution to help companies achieve profits.

▶ Multistage screening

▶ Can be screened according to customer needs

Based on our DG Leap control system, it can save human cost and be efficient and easy to operate. It adopts imported original components and equipped with 4G/5G Cloud control.

D&G self-developed know-how “secondary Intelligent bitumen measurement system” ensure the pre-set recipe can be implement with minimum deviation value. In the meantime, the waste of bitumen and other materials are eliminated.

▶ Four channels impacted rotor structure can increase crushing efficiency by 20-30%

▶ Adopts deep cavity type rotor, in this way, the material throughput can be increased by 30%.

▶ The curved channel design can reduce the flow resistance of materials, greatly improve the passage of materials and increase the production capacity of the machine.

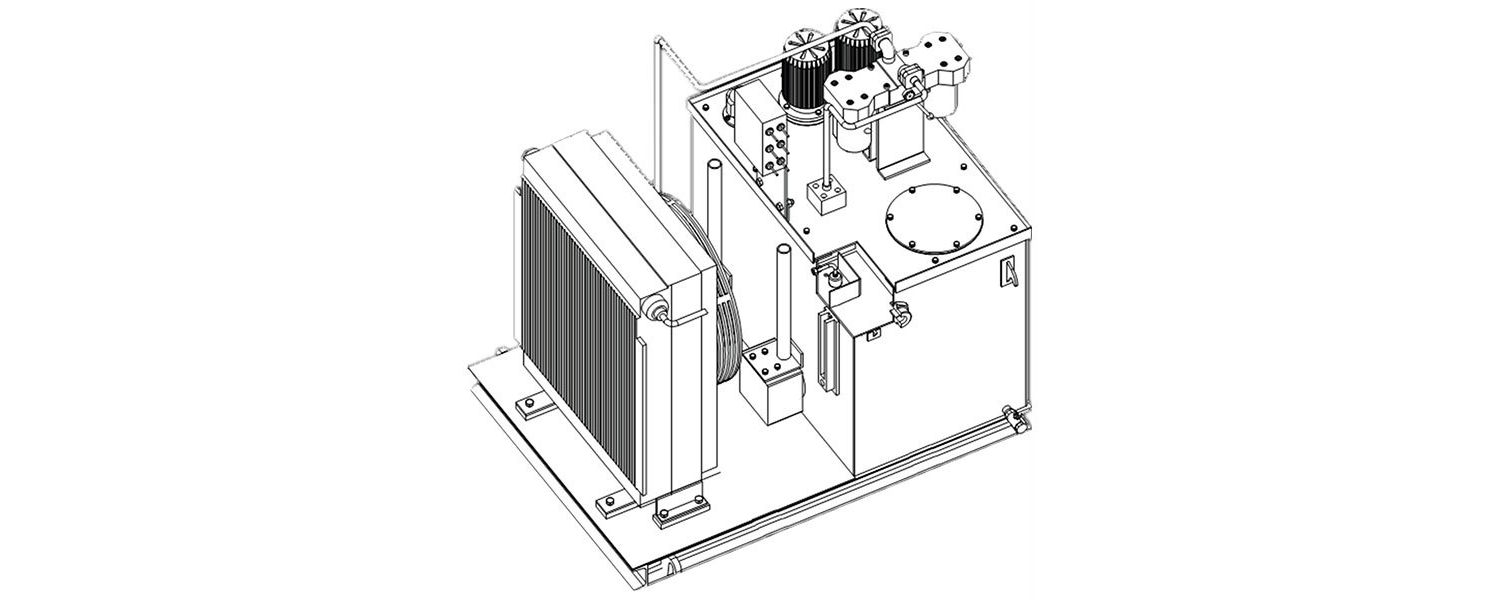

▶ Double oil pump supply

▶ Automatic shutdown in case of no oil flow or high oil temperature

▶ The cooling system and heating device work automatically

Model | MS100 | MS200 | MS300 | MS450 |

Feed Particle Size(mm) | 30mm | 35mm | 40mm | 50mm |

Production(0-4.75mm) | 30-50t/h | 50-100t/h | 100-150t/h | 150-260t/h |

Raw material throughput(≤40mm) | 50-100t/h | 100-200t/h | 200-300t/h | 200-300t/h |

Powder content(adjustable) | 3-18% | 3-18% | 3-18% | 3-18% |

Total power | / | / | ≈750kW | ≈950kW |

Power Supply | AC380V/50Hz | AC380V/50Hz | AC380V/50Hz | AC380V/50Hz |

Fineness modulus of finished material | 1.6-2.2 Sand for ready-mixed mortar can be adjustable | |||

2.3-3.2 Sand for commercial concrete can be adjustable | ||||

covers the total area | L20m x W30m (Subject to the actual situation on site) | |||