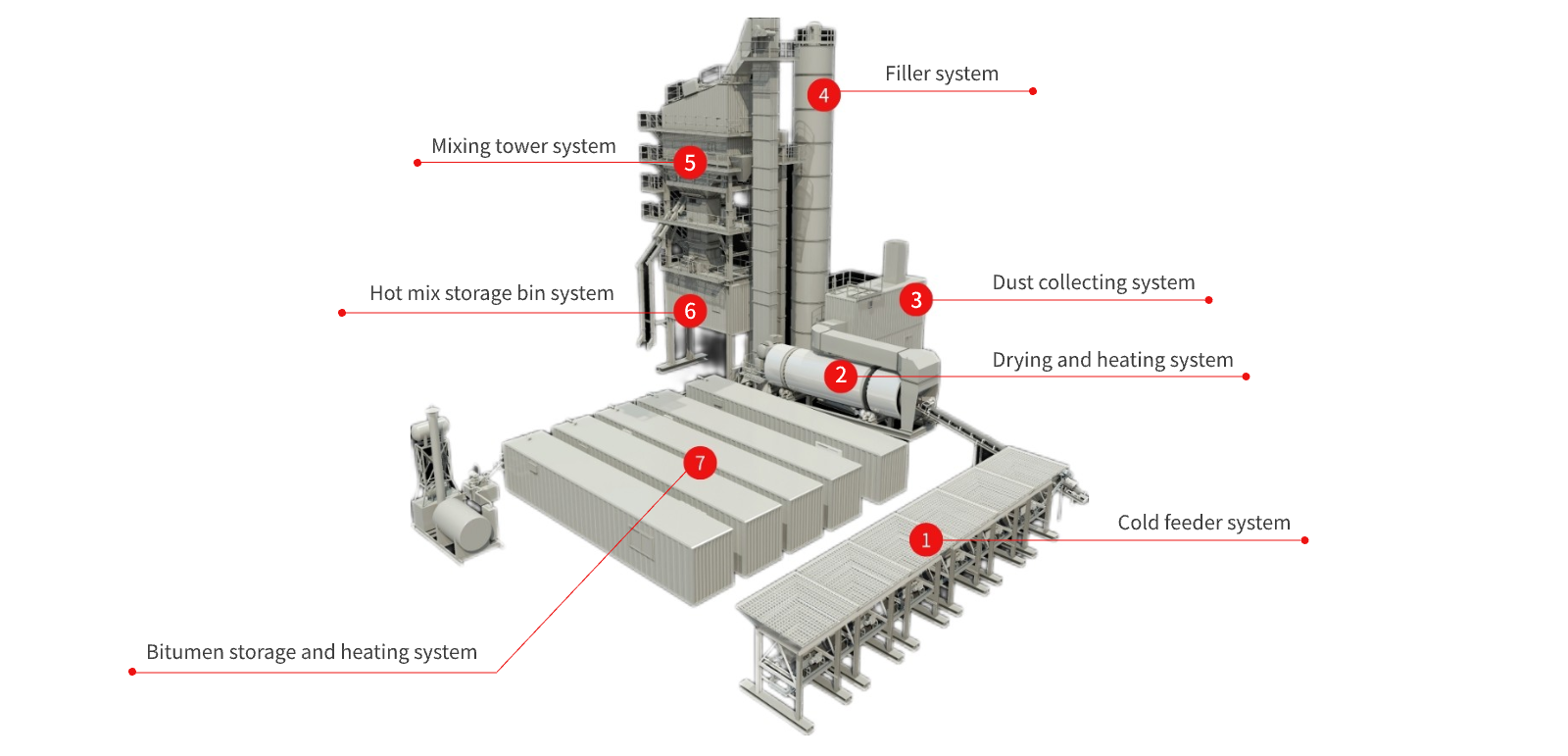

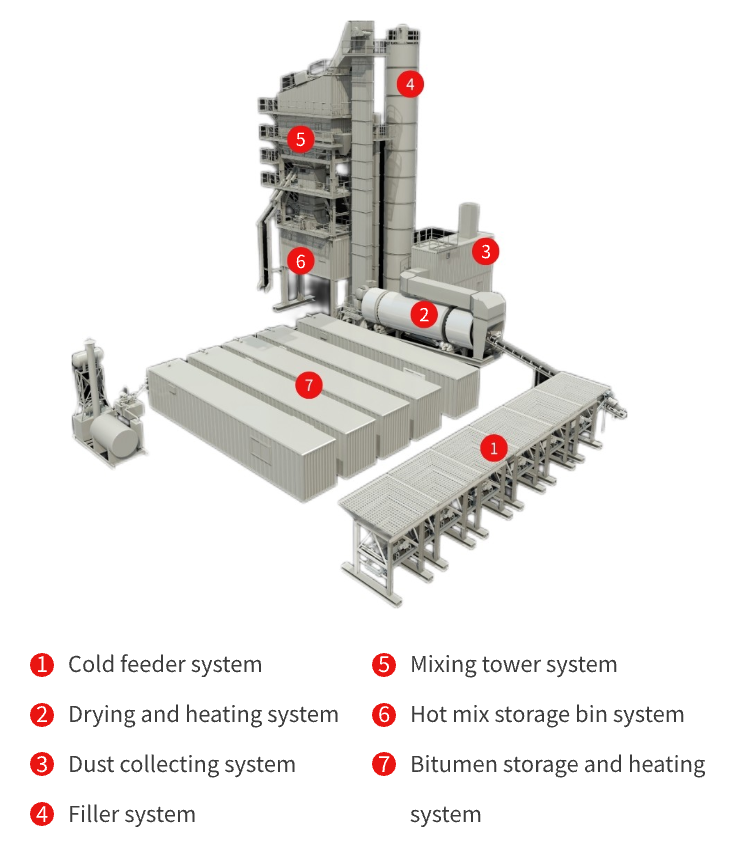

DG asphalt mixing plant is specialized for the export case that take by sea freight transport. The mix tower and bag house as well as the control room are designed in shipper owned container (SOC)model so that the delivery cost is greatly saved. Besides the feature for easy transport, it keeps the high end produce performance and components select are same to D&G standard series.

1.SOC (Shipper Owned Container)

The plant is designed in modular concept, we considered about the cost of sea freight and relocation chance in practice case. Foldable handrails &platforms and stairs are integrated with each module. Every module of the equipment is designed in SOC or can be put into 40 feet’s container. For transport locally, every module of plants can be taken by a 16m trailer.

With individual elements precisely selected and professionally configured for shipping container housings, the DG Compact minimizes transportation costs for customers. This design is perfectly integrated into D&G’s core features to guarantee a truly high level of productivity and hassle-free maintenance. Installation and relocation of the plants become further simper and quicker.

SPECIFICATION | ||||

MODEL-DGC Series | DGC1500AC | DGC2000AC | DGC2500AC | DGC3000AC |

Rated Production Capacity | 140t/h | 160t/h | 200t/h | 240t/h |

Dry Drum Size | Ø 1.9m x 9 m | Ø 2.0m x 9 m | Ø 2.2m x 9 m | Ø 2.5 x 9 m |

Dust Collector | Primary gravity+ Bag filter | |||

Screen | 6 | 6 | 6 | 6 |

Hot Bin Volume | 21 m³ | 21 m³ | 40 m³ | 40 m³ |

Mixer Capacity | 1500kg | 2000kg | 2500kg | 3000kg |

Mixer Drive Device | Twin-Shafts/ Gear motors | |||

Control System | DG Leap + PLC | |||

Emission Rank | ● Dust Density ≤ 20 mg/Nm³ | |||

● Cabin Noise ≤ 70 dB | ||||

● Ringelmann Blackness Class Ⅰ | ||||

Note | ● Specifications / options are constantly updated and subject to change. | |||

1) Adds grid plate at top of each hopper it can screen oversize aggregates.

2)Steel base design, requires no civil foundations (optional).

1) Shipper owned container(SOC) modular design. CSC CERTIFICATE

2) Reduce erection cost.

3) With famous transmission components.

1) The rolling rings and rollers are applying high strength wear-resisting material.

2) The cylinder adopts stainless steel plate, which gives it high temperature resistance and non-deformability.

3) The drum flights are applied in HARDOX high strength wear-resistance steel to prove long service time.

1) Two stage dust filtration system: primary gravity+ bag filter.

2) Low emission. Ringelmann Blackness ClassⅠ.

1) "DG LEAP" Automatic and manual control can be switched.

2) System configured with Siemens PLC.

1) Circulating pump to control the bitumen flow.

2) Quantity of bitumen tank is changeable.

3) Electric heating tank is optional.