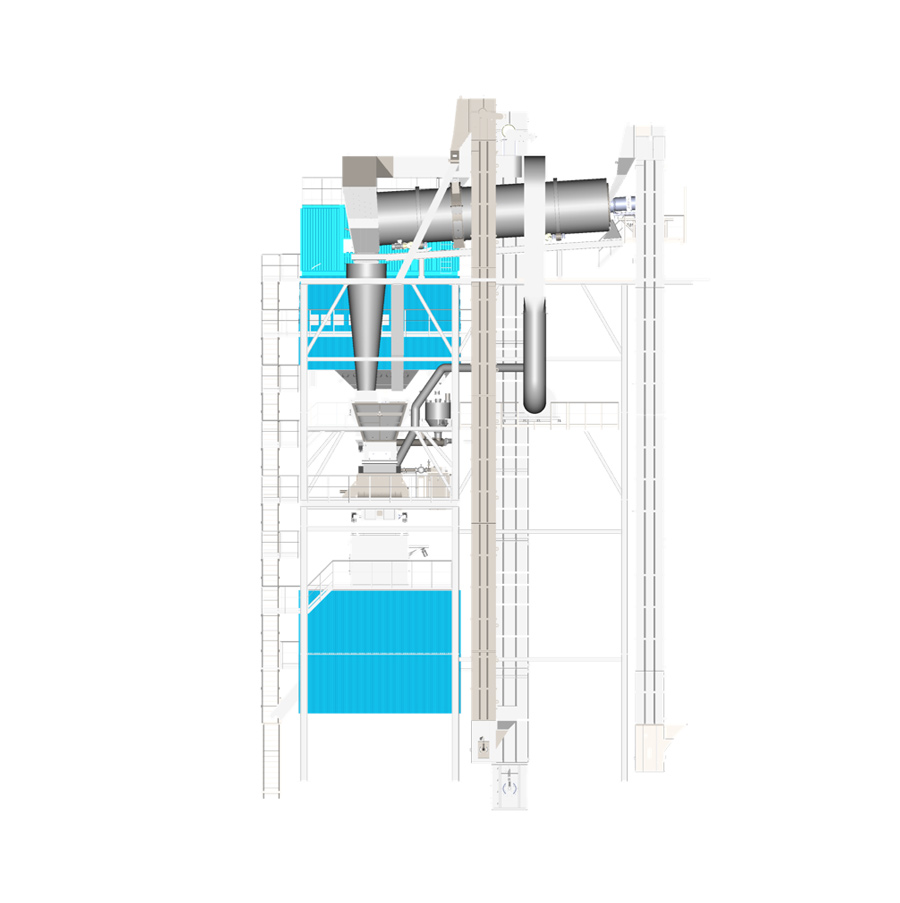

The material flow direction is the same as the fume direction.In the case of Parallel Flow heating, the temperature difference between the exhaust gas and the RAP is within 10 degrees. The RAP fume enters the new aggregate drum for secondary combustion and then the dust collector for discharging without energy waste.RAP Heating Temperature: Equipped with special rake teeth and supporting flexible cleaning device, the RAP can be heated to 160℃.Aging of Asphalt: D&G Machinery uses ABS burner featuring better flame control. In addition, the special structure of the combustion zone prevents the recycled material from being burned by the flame.RAP Addition Ratio: 40-80% of RAP can be added thanks to the high discharge temperature, reaching 160-170℃.Recycled Fine Material: Small fume volume means no recycled fine material would be sucked away.Relatively easy,equipment procurement cost low,usage cost low.

Parallel Flow

● Heating Direction: The material flow direction is the same as the fume direction

● Heating Efficiency: In the case of Parallel Flow heating, the temperature difference between the exhaust gas and the RAP is within 10 degrees. The RAP fume enters the new aggregate drum for secondary combustion and then the dust collector for discharging without energy waste.

● RAP Heating Temperature: Equipped with special rake teeth and supporting flexible cleaning device, the RAP can be heated to 160℃.

● Aging of Asphalt: D&G Machinery uses ABS burner featuring better flame control. In addition, the special structure of the combustion zone prevents the recycled material from being burned by the flame.

● RAP Addition Ratio: 40-80% of RAP can be added thanks to the high discharge temperature, reaching 160-170℃.

● Recycled Fine Material: Small fume volume means no recycled fine material would be sucked away.

● Control System: Relatively easy

● Equipment Procurement Cost: Low

● Usage Cost: Low

China

Jiangxi Province, China

Anhui Province, China

Capacity | 80-260t/h(Moisture content 3%) |

RAP Addition Ratio | 40-80% |