D&G Machinery's Warm-Mix Foaming Technology: Cracking the "Temperature Code" for Bitumen with High Rubber Powder Content

Against the backdrop of promoting the green and low-carbon transformation of transportation infrastructure, a project jointly undertaken by Beijing Zhonglu Gaoke Highway Technology Co., Ltd. (hereinafter referred to as Zhonglu Gaoke) and Langfang D&G Machinery Technology Co., Ltd. (hereinafter referred to as D&G Machinery) has made big progress. D&G Machinery has carried out warm-mix foaming device retrofitting for a customer's 4000-model asphalt mixing plant, enabling the production of foamed warm-mix asphalt mixtures with a high content of rubber powder. This mixture has been successfully applied in the reconstruction and expansion project of the Shijiazhuang-Taiyuan Expressway. This technological breakthrough not only enhances the resource utilization of waste tires but also provides a new solution for the green construction of high-grade highways in China.

Technological Innovation: The Synergistic Advantages of Warm-Mix Foaming and High Rubber Powder Content

The production of traditional hot-mix asphalt mixtures requires high-temperature heating (usually above 160°C), resulting in high energy consumption and the generation of substantial greenhouse gases and harmful emissions. In contrast, as for D&G Machinery's warm-mix foaming device, only a small amount of water and compressed air need to be injected, enabling bitumen physical foaming at a lower temperature. This process forms uniformly foamed bitumen, significantly lowering both the mixing and construction temperatures.

Industry-University-Research Collaboration: Bridging the Gap from Laboratory to Engineering Practice

This project is a good example of collaborative innovation through industry-university-research cooperation. As the technical demander and application entity, Zhonglu Gaoke worked closely with D&G Machinery, which provided equipment upgrading and engineering support. Through multi-party collaboration, Zhonglu Gaoke 's 4000-model asphalt mixing plant was successfully upgraded into an efficient device that combines warm-mix functionality with the capability to process high-content rubber powder. This achievement marked the successful transition of the technology from the laboratory to industrial-scale application.

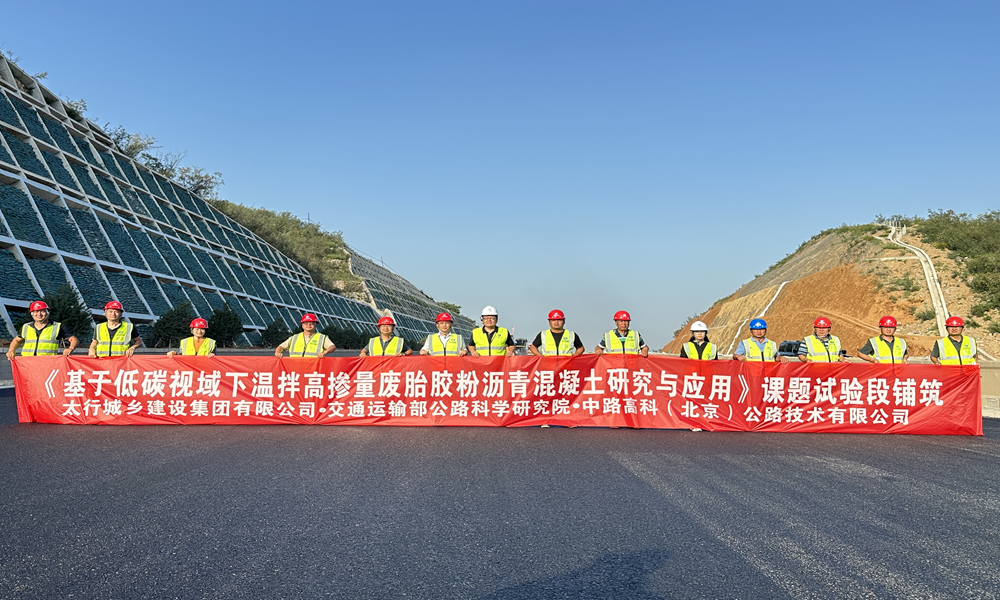

Engineering Application: Green Practice in the Reconstruction and Expansion of the Shijiazhuang-Taiyuan Expressway

The Shijiazhuang-Taiyuan Expressway, as a vital transportation artery in North China, has strict requirements for material performance and environmental protection in its reconstruction and expansion project. The warm-mix high-content rubber powder asphalt mixture produced for this project was used for paving the upper and middle layers of the road pavement. D&G Machinery's warm-mix foaming device features many advantages:

Environmental Benefits

Significantly reducing carbon emissions and energy consumption, while utilizing a large amount of waste tires.

Performance Enhancement

Rubber powder modification enhances the rutting resistance and crack resistance of the asphalt mixture, meeting the demands of heavy-duty traffic.

Construction Improvements

The warm-mix technology reduces on-site paving temperatures, improving the working environment for workers and extending the construction window.

Industry Significance: Paving a New Path for Green Highway Construction

The collaboration between D&G Machinery and Zhonglu Gaoke is more than just a technological upgrade of equipment, it also reflects the asphalt mixing industry shifting towards greener and more advanced development. The successful application of warm-mix high-content rubber powder asphalt technology provides a replicable and eco-friendly solution for China's highway reconstruction and expansion projects, aligning with the national "dual carbon" goals and circular economy policies.

Looking ahead, D&G Machinery will continue to advance innovative technologies, so as to promote sustainable development in transportation infrastructure construction through wider adoption in major engineering projects.