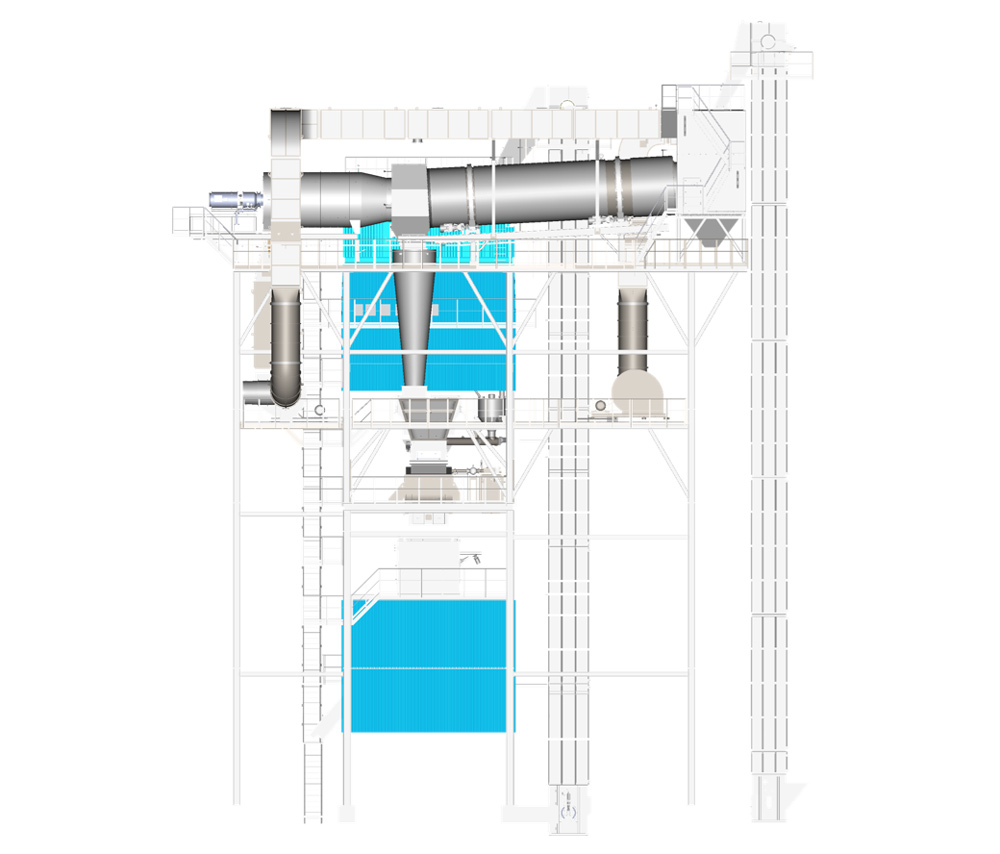

The material flow direction is opposite to the fume direction.In the case of Counter Flow heating, theoretically, the RAP fume has a low emission temperature. A secondary combustion method is adopted by D&G Machinery by which the RAP dryer drum fume enters the main drum and the dust collector respectively. The harmful gases in the fume are burned in the main drum to reduce the damage to the bag filter.Equipped with special cleaning chain design in the drum, the RAP can be heated above 160℃. The design also results in less sticking of RAP inside the drum, making it easier to form a “material curtain” and bringing low fume temperature.The recycled old material (RAP) is indirectly heated by means of hot gas-flameless contact to effectively prevent the volatilization of bitumen components in RAP and reduce asphalt aging.50-100% of RAP can be added thanks to the high discharge temperature.Since the volume of RAP fume is relatively large, the Recycled Fine Material would be easily carried away by the hot air. Generally, when using Counter Flow, the fine material is directly fed into the mixer.Relatively complicated,Relatively high. Furnace: Medium and low temperature hot blast stove, horizontal structure, generates hot air at 450℃-600℃, aluminum silicate ceramic fiber is used as the refractory layer inside, and the inside is also coated with high-temperature thermal protective coating to further protect the furnace. The burner end of the furnace is equipped with a flame area protective layer, which is made of heat-resistant stainless steel and has excellent performance to effectively prevent flame contact.

Counter Flow

● Large RAP Addition Ratio: 50-100% of RAP can be added thanks to the high discharge temperature.

● Heating Direction: The material flow direction is opposite to the fume direction

● Heating Efficiency: In the case of Counter Flow heating, theoretically, the RAP fume has a low emission temperature. A secondary combustion method is adopted by D&G Machinery by which the RAP dryer drum fume enters the main drum and the dust collector respectively. The harmful gases in the fume are burned in the main drum to reduce the damage to the bag filter.

● RAP Heating Temperature: Equipped with special cleaning chain design in the drum, the RAP can be heated above 160℃. The design also results in less sticking of RAP inside the drum, making it easier to form a “material curtain” and bringing low fume temperature.

● Aging of Asphalt: The recycled old material (RAP) is indirectly heated by means of hot gas-flameless contact to effectively prevent the volatilization of bitumen components in RAP and reduce asphalt aging.

● Recycled Fine Material: Since the volume of RAP fume is relatively large, the Recycled Fine Material would be easily carried away by the hot air. Generally, when using Counter Flow, the fine material is directly fed into the mixer.

● Control System: Relatively complicated

● Equipment Procurement Cost: Relatively high

● Recycled dry drum dose not stick

● Optional Function Expansion Devices:

RAP cold recycling system

Rejuvenator metering and adding device

Warm-mix asphalt foaming device

Flocculent / fibrous / pellet additive

Liquid additive metering and adding device

Allowing Production of Various Types of Mixtures:

Regular asphalt mixture

Reclaimed asphalt mixture

Warm mix asphalt mixture

Colored asphalt mixture

Special asphalt mixture(e.g. SMA/high modulus asphalt)

Capacity | 160t/h – 260t/h |

RAP Adding Proportion | 60%-100% |