Warm-mix Asphalt Foaming Device

| Parameter | |

| Model | TFB10 |

| Size(LxWxH) | 1640x720x1065mm |

| Bitumen Rated Flow | 12 L/min |

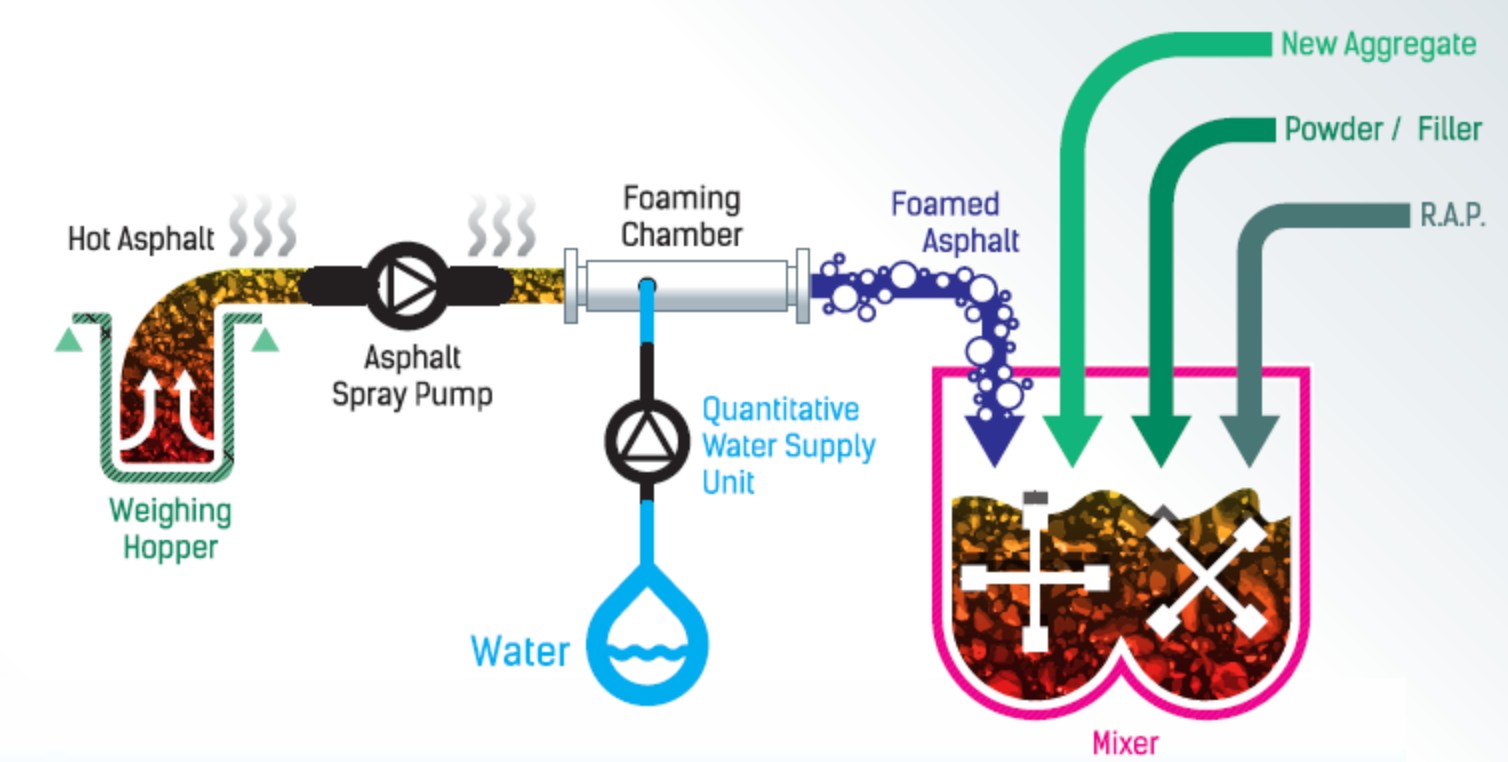

| Foam Medium | Water (normal temp.), Gas (optional) |

| Temperature | Appr.160℃ |

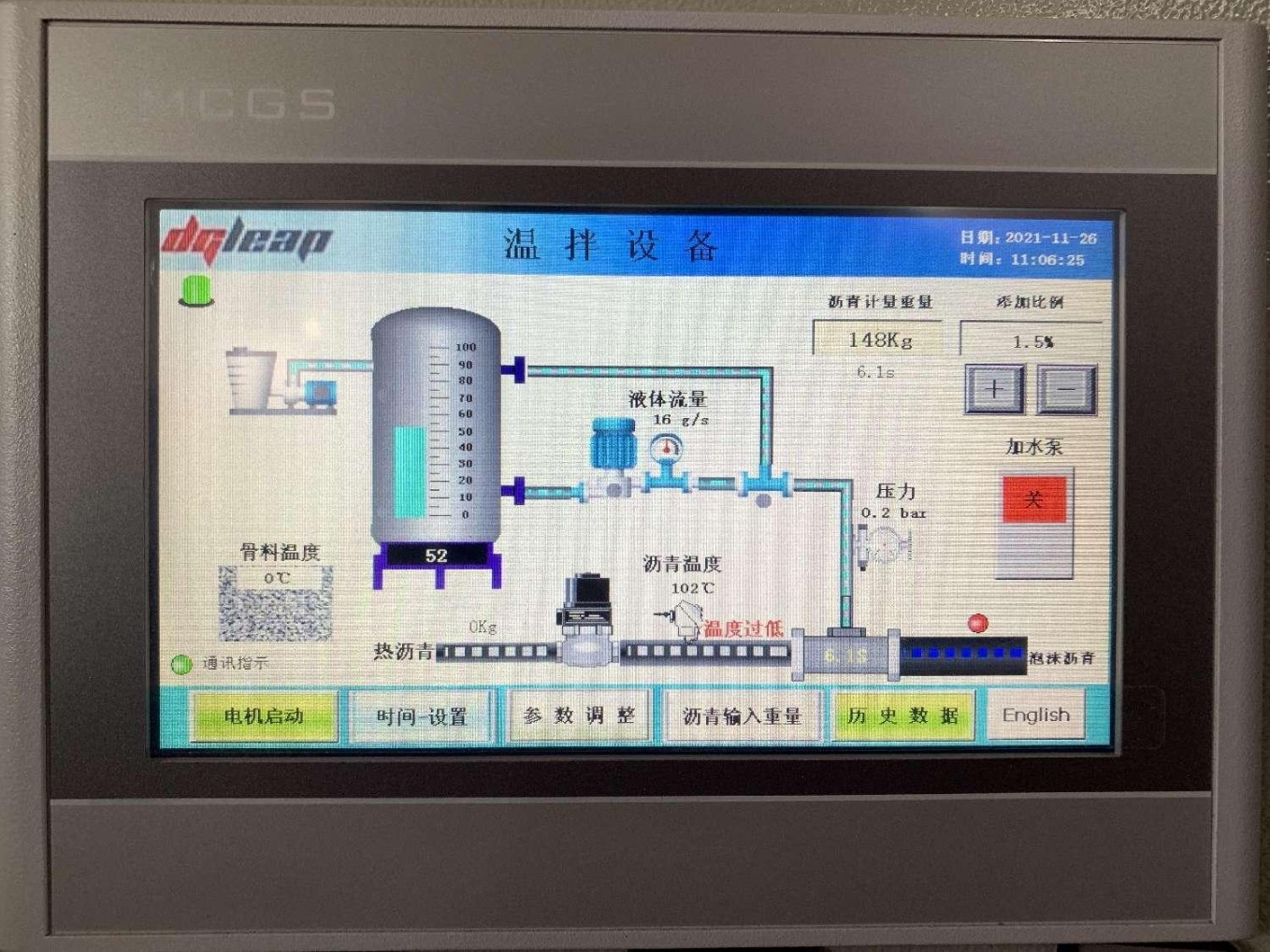

| Water Pump Rated Flow | 0.06-0.6 L/min (adjustable frequency ) |

| Water Content | Ordinary:1-3%, modified:2-4% |

| Water Pressure | Appr. 1.6 Mpa |

| Bitumen Tank Volume | 12L |

| Water Tank Volume | 2.4L |

| Total Power | 5kW |