China's Premium Asphalt Plant Manufacturer | D&G Machinery Stock Code 1301.HK | Completely Road Construction Solutions Provider, Pursuing Excellence

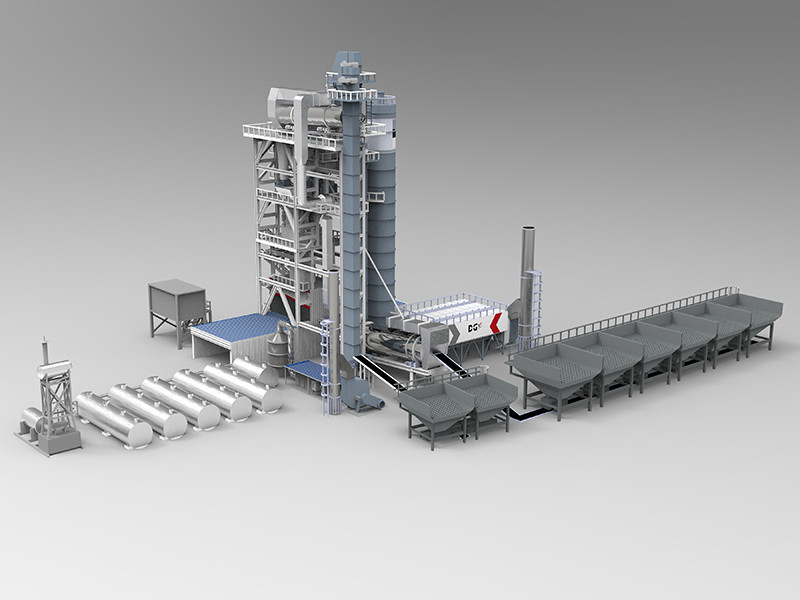

DGXR Asphalt Mixing Plant

| Categories | RAP Batch Asphalt Mixing Plant |

|---|---|

| Brand | D&G Asphalt Plant Manufacturer |

| Model | DGXR2000-DGXR5000 |

| Mixer Capacity | 2000-5500kg |

| Control System | DG Leap + PLC |

| Dust Collector | Primary gravity+ Bag filter |

| RAP adding proportion | 50%-100% |

| Features | RAP series, large RAP proportion |

| FOB port | TIANJIN |

| Terms of Payment | L/C, T/T |

| Update Time | Nov 14,2024 |

Detail Information

- If you are planning to establish an asphalt mixing plant and would like to know about cost budgeting and how to select and price asphalt mixing plants, we will provide you with more technical support regarding the early stages of your asphalt mixing plant. Additionally, if you wish to become a distributor of DG's localized asphalt mixing plant, we will offer you more support to expand your local market. Contact us now for more information about DG asphalt mixing plant consultations.

DGXR Asphalt Mixing Plant 180t/h-400t/h

DGXR asphalt mixing plant allow user to apply 50%-100% reclaimed asphalt to effect eco-friendly and more economic hot mixture produce. According to the different situation, customer can choose put RAP equipment to virgin plant in the way of recondition or order a monoblock recycling asphalt plant to get the max application of reclaimed asphalt material.

DGXR Asphalt Mixing Plant Features:

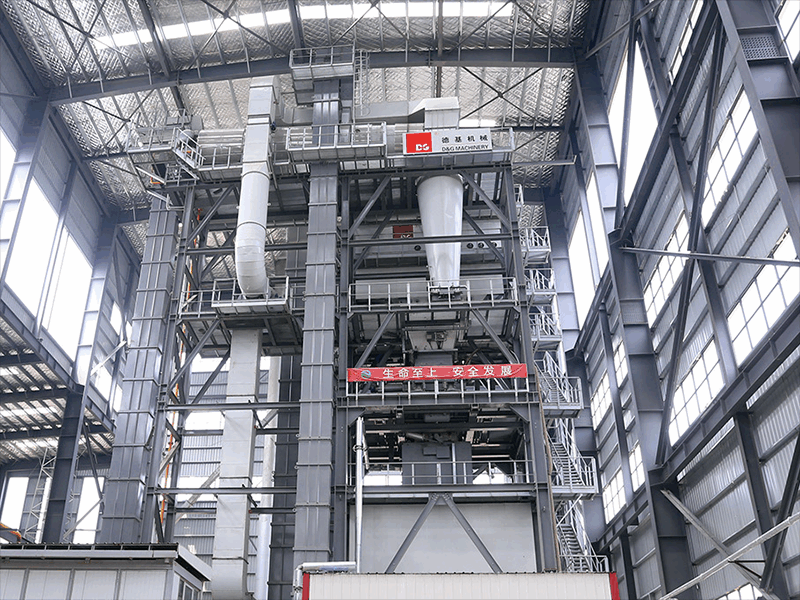

1. Regeneration Drying System

RAP Drum Heating Aggregates

Coarse/Fine RAP Aggregates are Separated

2. Large RAP Proportion

Asphalt mixing plant allow user to apply 50%-100% reclaimed asphalt to effect eco-friendly and more economic hot mixture produce.

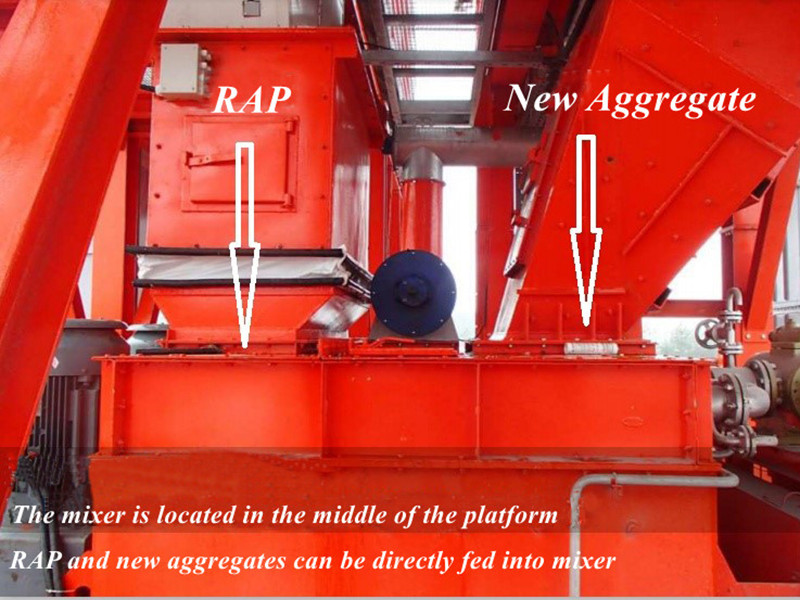

Mixer:The RAP Monoblock asphalt mixing plant adopts a larger mixer , which can guarantee the output of equipment, even if the mixing time is prolonged.The mixer is located in the middle of the “Integral Type”, which ensure RAP and new aggregates can be directly fed into mixer with measured by each own hopper.

Drying System:Optimized dryer drum circulates hot air before exhaust, and the heat utilization rate is high.Asphalt flue gas and harmful gas circulate into the drying drum and burn again, which greatly reduce harmful flue gas emissions.

Drying drum with thermal insulation to avoid energy loss.

Mixer

RAP Section

3.Fast Production Pace and Convenient Maintenance

D&G MACHIENRY'asphalt recycling plant has a fast production pace can meet customer's the needs of planning period. Meanwhile, the plant has an integral structure and is easy to maintain.

Control System

Mixing Tower

DGXR Asphalt Mixing Plant Parameters

SPECIFICATION | |||||

MODEL-DGXR Series | DGXR2000 | DGXR3000 | DGXR4000 | DGXR4500 | DGXR5000 |

Rated Production Capacity | 180 t/h | 240 t/h | 320 t/h | 360 t/h | 400 t/h |

Dryer Drum Size | Ø 2.2m x 9m | Ø 2.5m x 9m | Ø 2.8m x 12m | Ø 2.8m x 12m | Ø 3.0m x 12m |

Dryer Drum Capacity(Aggregate moisture content 5%) | 180 t/h | 240 t/h | 320 t/h | 320 t/h | 400 t/h |

Dust Collector | Primary gravity+ Bag filter | ||||

|

Screen

|

5 |

5 or 6

|

6 |

6

|

6 |

RAP Adding Percentage+Dryer Drum Capacity(Aggregate moisture content 5%) | 50-100%/ 160t/h | 50-100%/ 160t/h | 50-100%/ 160t/h | 50-100%/ 160t/h | 50-100%/ 200t/h |

Dryer Drum Size | Ø 2.2m x 11m | Ø 2.2m x 11m | Ø 2.2m x 11m | Ø 2.2m x 11m | Ø 2.5m x 11m |

Hot Bin Volume | 21m³ | 45m³ | 75m³ | 75m³ | 80m³ |

Mixer Capacity | 2000kg | 3300kg | 4200kg | 5500kg | 5500kg |

Control System | DG Leap + PLC | ||||

Emission Rank | ● Dust Density ≤ 20 mg/Nm³ | ||||

● Cabin Noise ≤ 70 dB | |||||

● Ringelmann Blackness Class Ⅰ |

|||||

|

Note:

|

|||||

|

● Some specifications / options might not be available in some countries due to local regulations.

|

|||||

● Specifications / options are constantly updated and subject to change. | |||||

Review

- Loading...

Related Products

Leave Your Info, Get the Best Solution Soon!

Interested in becoming a distributor? Please fill out this form and we will contact you for further discussion.

- Name

- Tel

- *Title

- *Content