Working Principle of Asphalt Mixing Plant

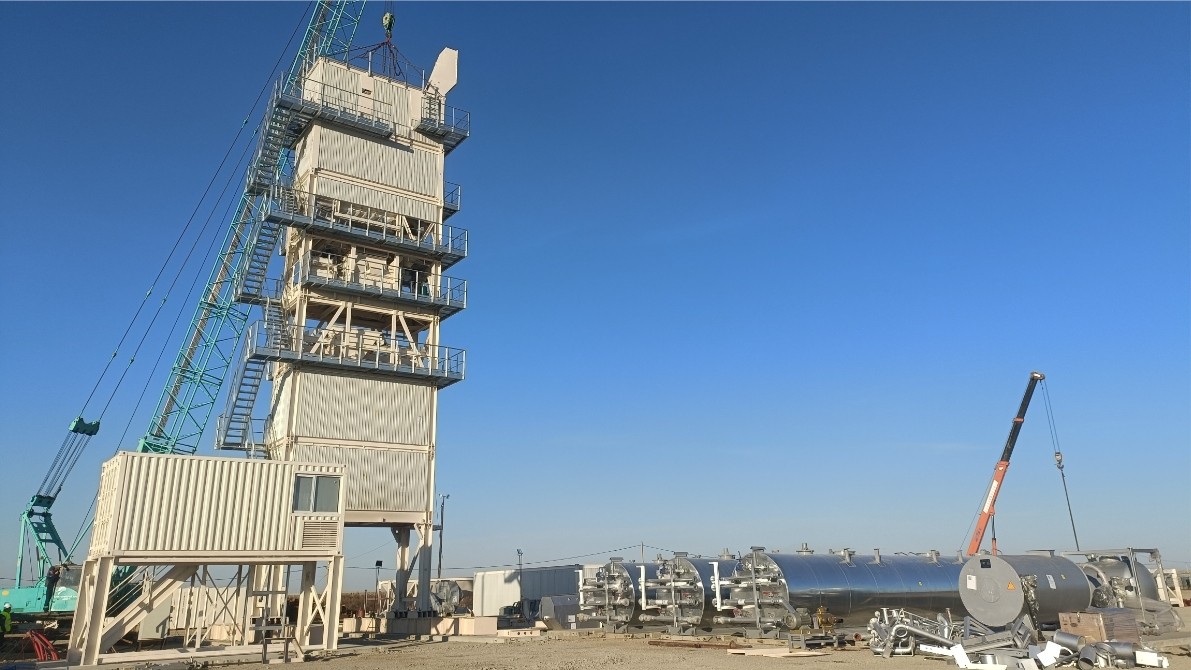

Asphalt mixing plants are used to mix a variety of aggregates with asphalt to make hot-mix paving materials for many construction industries. The aggregate used can vary depending on the grade and size of asphalt desired. It is also possible to add finer aggregates as well as mineral fillers. There are two main forms of asphalt mixing plants: continuous mixing plants and batch mixing plants. Both plants produce bitumen, and their difference lies in the process by which said bitumen is produced.

Working Principle of Asphalt Mixing Plant

1. Unheated raw aggregates from different storage silos are fed into the cold aggregate feeder.

2. The aggregate enters the drying drum through the conveying system.

3. The burner provides fuel for the drying drum to ensure that the aggregate is heated and dried effectively.

4. The factory is equipped with a primary dust collector. This dust collector is specially designed to filter heavier dust particles, so there is less pollution.

5. After the aggregate is dried, it is immediately transferred to the tower unit by the bucket elevator.

6. The units near the top of the tower are true multi-layer shielded units. As hot aggregates pass through multiple screens, they are subject to the screening effect.

7. Use independent thermal warehouses to store different types of aggregates.

8. Bitumen is stored and heated in special tanks equipped with pumping equipment. Bitumen is pumped into a weighing hopper.

9. Aggregate is weighed and discharged in the main mixing unit. Inside the mixer, filler and bitumen are mixed with aggregate.

10. After mixing for the desired time, the hot asphalt is ready to be applied. It's actually usually discharged into a waiting pile, but it's also sent to temporary storage silos.

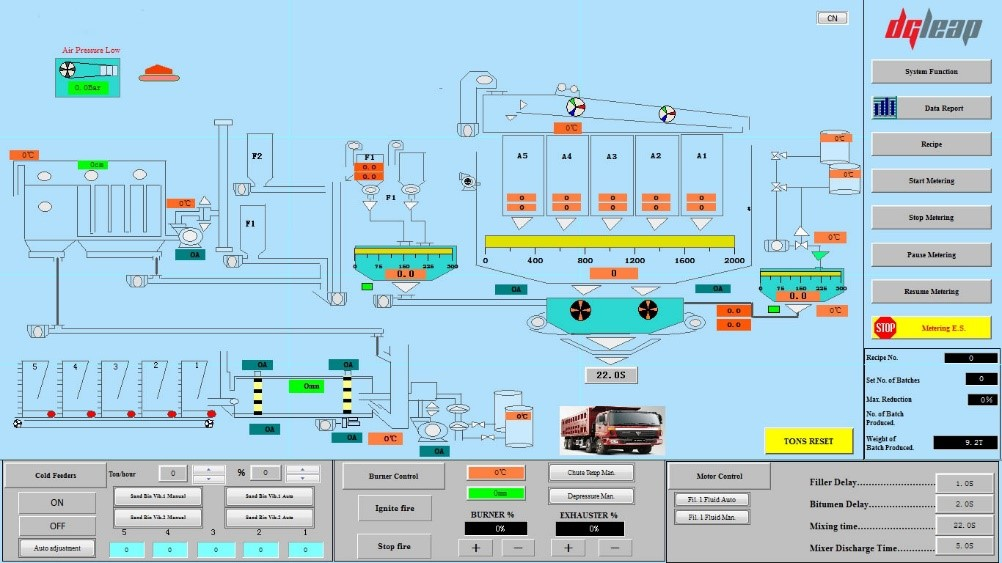

11. The whole factory is controlled by a computerized panel.

Elements of an Asphalt Plant

Primary vibrating screen

Cold storage bin

Drying drum with burner

perhaps the most important part of the plant. It's actually a compromise between a drum and a burner unit. Rotation ensures even heating of the aggregate.

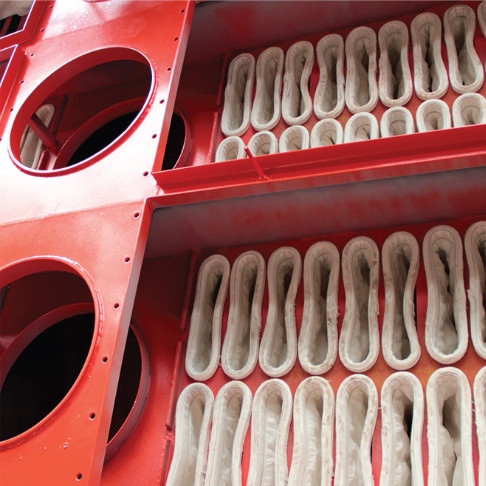

Pre-separator with bag filter

The bag filter is used to remove harmful dust particles and toxic gases discharged from the factory.

Hot mix storage bin

Multi-layer vibrating screen

Mixing device

The mixing device ensures that each raw material is effectively mixed at the correct time. Mixers are usually jacketed so that the contents remain hot and ready to discharge.

Bitumen storage tanks

Directly heated storage tanks have burners. Meanwhile, indirectly heated tanks utilize an internal hot oil coil system to heat the bitumen.

Panel

PLC panel adopts touch screen display and interface, which is convenient for on-site and factory power-on.

Filler storage silos/hoppers