Unlocking the "New Form" of DGX

At 10:00 am on July 2nd, 2020, the world's first "DGX" from D&G Machinery was officially released. This conference attracted nearly 4,000 people. Therefore, thanks to our friends from all over the country for their attention and support to D&G Machinery.

Unfortunately, some friends have not been able to watch the live broadcast due to time schedule. But never mind, we especially prepare a detailed introduction of the new "DGX" product.

One equipment with multiple types, integration by requirements

DGX adopts the idea of cross model planning and design, and the functional modules are integrated according to different modes to realize the conversion of different equipment styles and functions to meet the different requirements for different production conditions.

「Conventional type」VS「Integral type」

「Conventional type」

The equipment is reassembled into "Integral type" through later upgrading.

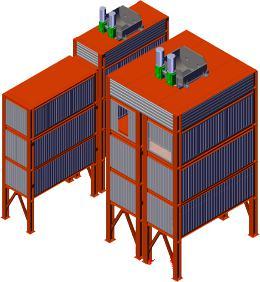

「Integral type」

According to the actual production needs, only the necessary functional modules can be reserved and assembled according to the "Conventional style”.

HMA storage bin system under mixer

The installation can be selected according to the engineering and process demands, which will greatly simplify the plant structure and reduce installation /debug time and costs.

“Integrated type” main tower cladding

Integrated designs under different forms, such as cladding of main tower and other environmental protection related configuration, can be selected as required.

Most of the functional modules can be used among multiple equipments of the same model or adjacent models.

Modular integrated storage bin

Modular storage bin selection method

Modular structure design and many selection methods meet the diversified needs of users for the finished product storage bin system.

Selection methods for storage bin under mixer

Translational skip Swing chute Orthogonal skip Swivel chute

Typical product storage bin combination

Single-span bin equipped with swing chute /translational skip

type double/multiple bins equipped with translational skip

type double/multiple bins equipped with orthogonal skip

Double span bins with double/multiple compartments with orthogonal skip

Storage bins with double/multiple compartments equipped with orthogonal skip type double bins equipped with swivel chute

Double span bins with 2 compartments equipped with swivel chute

Storage bins with double compartments equipped with swivel chute

Multiple recycling combinations mode

「Separation of recycled aggregate and fine」

Recycling dryer drum equipped with "recycling ring" system

The fine RAP is heated by the drum through the recycling ring

"Combination of cold and hot"

In conjunction with a separate "cold drop” system, the fine RAP is added by the cold drop system, or the cold drop system is used alone with a lower recycling rate.

「Parallel-flow heating」recycling drying system

Mature technology

Conventional matching

Cost-effective

「Counterflow air heating furnace」recycling drying system

Higher ratio

Lower emissions

Safer

"Diversified " expansion "Multifunctional" production

Recycling cold drop system

Recycling agent metering and feeding device

Warm mix asphalt foaming device

Powder / particle additive metering and feeding device

Liquid additive metering and feeding device

Various types mixture production function

Conventional hot mix asphalt

Recycled asphalt mixture

Warm mix asphalt mixture

Color asphalt mixture

Special asphalt mixture(Such as SMA, etc )

As a member of China's manufacturing industry, D&G Machinery has been making great efforts in the past 20 years, carrying the heavy trust by means of science and technology. Adhering to innovation-driven development and quality priority is the tireless pursuit of D&G people. The changeable DGX is a gift of D&G Machinery for the road construction of the motherland!