China's Premium Asphalt Plant Manufacturer | D&G Machinery Stock Code 1301.HK | Completely Road Construction Solutions Provider, Pursuing Excellence

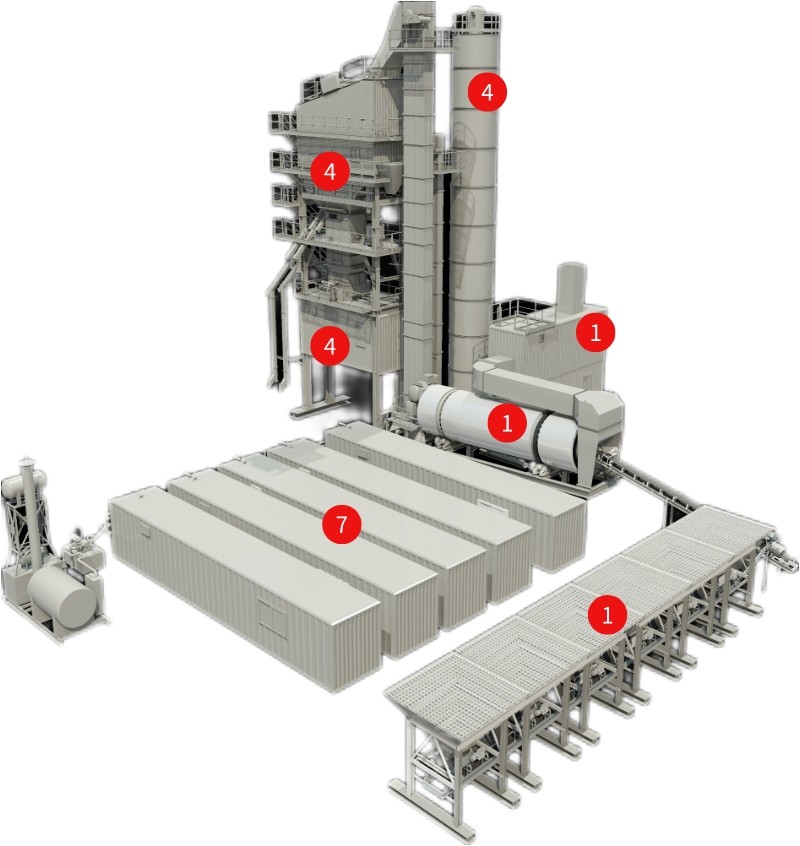

DGC Asphalt Mixing Plant

| Categories | SOC Batch Asphalt Mixing Plant |

|---|---|

| Brand | D&G Asphalt Plant Manufacturer |

| Model | DGC1500-DGC3000 |

| Dust Collector | Primary gravity+ Bag filter |

| Control System | DG Leap + PLC |

| Place of Origin | China |

| Total Power | 420-500 KW |

| Transport and Installation | Containerised Series with quick erection |

| FOB port | TIANJIN |

| Terms of Payment | L/C, T/T |

| Update Time | Nov 14,2024 |

- If you are planning to establish an asphalt mixing plant and would like to know about cost budgeting and how to select and price asphalt mixing plants, we will provide you with more technical support regarding the early stages of your asphalt mixing plant. Additionally, if you wish to become a distributor of D&G's localized asphalt mixing plant, we will offer you more support to expand your local market. Contact us now for more information about D&G machinery asphalt mixing plant consultations.

Hot Aggregate Bin

Mixer

SPECIFICATION | ||||

MODEL-DGC Series | DGC1500AC | DGC2000AC | DGC2500AC | DGC3000AC |

Rated Production Capacity | 140t/h | 160t/h | 200t/h | 240t/h |

Dry Drum Size | Ø 1.9m x 9 m | Ø 2.0m x 9 m | Ø 2.2m x 9 m | Ø 2.5 x 9 m |

Dust Collector | Primary gravity+ Bag filter | |||

|

Screen

|

6

|

6 |

6

|

6 |

Hot Bin Volume | 21 m³ | 21 m³ | 40 m³ | 40 m³ |

Mixer Capacity | 1500kg | 2000kg | 2500kg | 3000kg |

Mixer Drive Device | Twin-Shafts/ Gear motors | |||

Control System | DG Leap + PLC | |||

Emission Rank | ● Dust Density ≤ 20 mg/Nm³ | |||

● Cabin Noise ≤ 70 dB | ||||

|

● Ringelmann Blackness Class Ⅰ

|

||||

|

Note:

|

||||

|

● Some specifications / options might not be available in some countries due to local regulations.

|

||||

● Specifications / options are constantly updated and subject to change. | ||||

1) Adds grid plate at top of each hopper it can screen oversize aggregates.

2)Steel base design, requires no civil foundations (optional).

1) Shipper owned container(SOC) modular design. CSC CERTIFICATE

2) Reduce erection cost.

3) With famous transmission components.

1) The rolling rings and rollers are applying high strength wear-resisting material.

2) The cylinder adopts stainless steel plate, which gives it high temperature resistance and non-deformability.

3) The drum flights are applied in HARDOX high strength wear-resistance steel to prove long service time.

1) Two stage dust filtration system: primary gravity+ bag filter.

2) Low emission. Ringelmann Blackness ClassⅠ.

1) "DG LEAP" Automatic and manual control can be switched.

2) System configured with Siemens PLC.

1) Circulating pump to control the bitumen flow.

2) Quantity of bitumen tank is changeable.

3) Electric heating tank is optional.

- Loading...

Leave Your Info, Get the Best Solution Soon!

- Name

- Tel

- *Title

- *Content